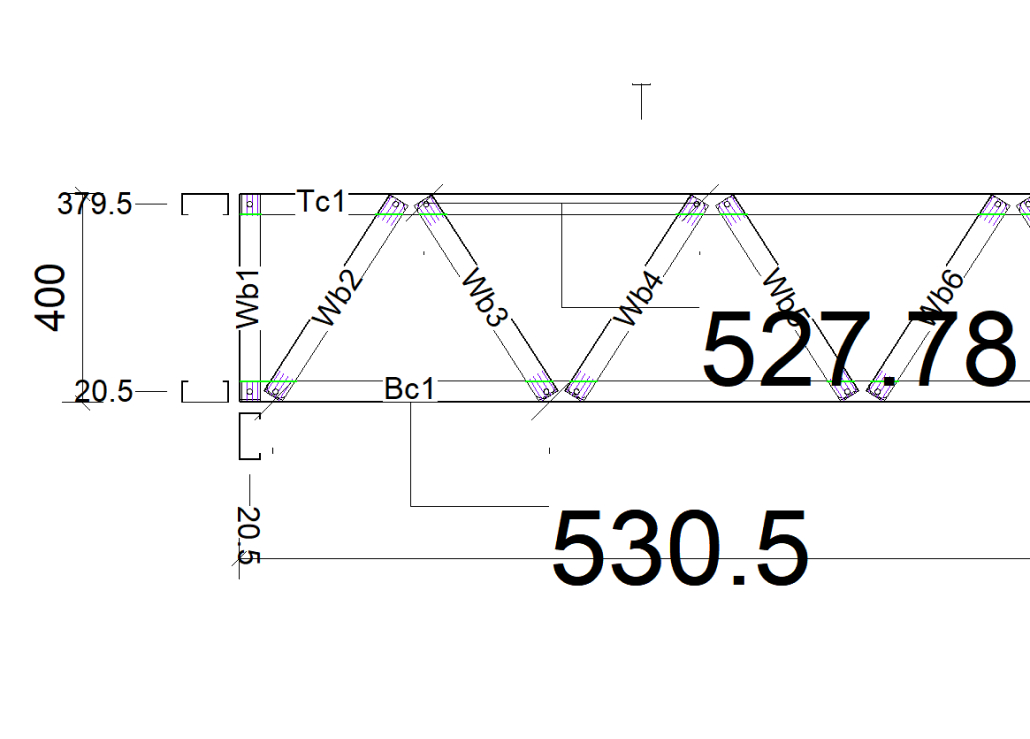

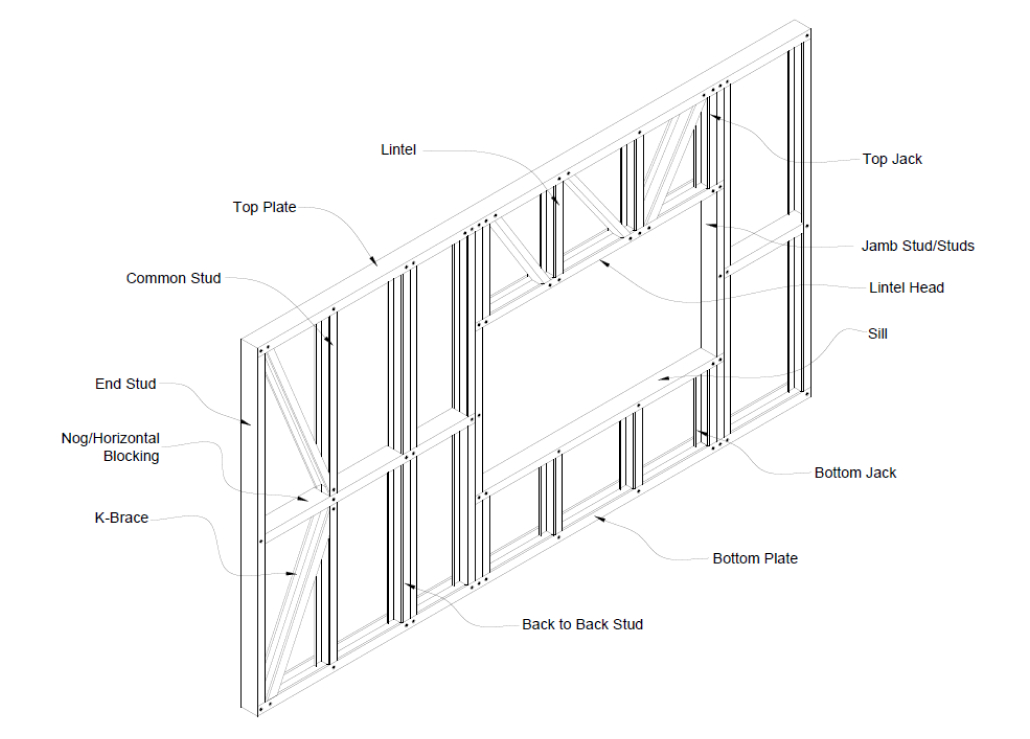

G550 with hot dip galvanizing Z275

The G550 is the ideal steel specification for all applications of structural steel frames, large and small size houses, specially modified architectural designs or an airy space for professional uses.

Quality G550 is structural steel with galvanized thermal coating, specially developed to maximize the efficiency of steel construction projects. G550 quality steel provides the highest output power of 550MPa, to minimize the total steel requirement in each of the structures and lower construction costs. Most importantly, it comes with full certificates of conformity, to ensure that the specifications of the materials comply with International Standards.